1、 How is engineering plastic defined?

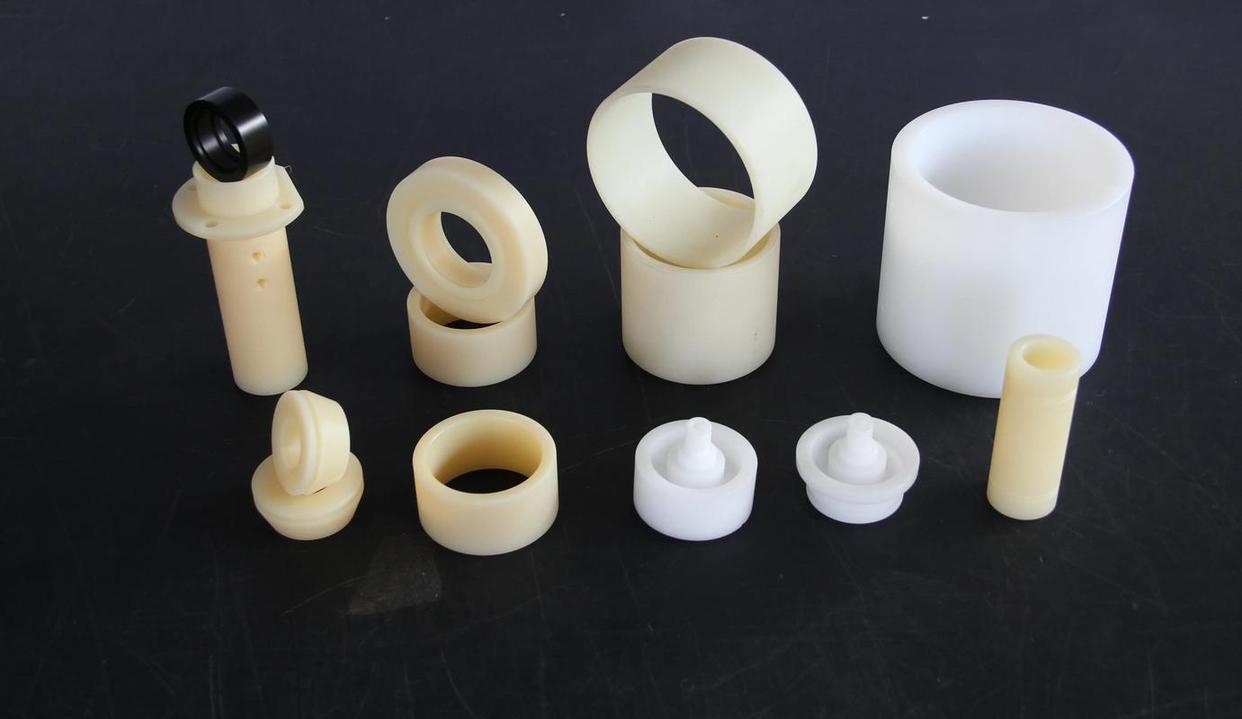

Engineering plastics generally refer to plastic materials that can withstand mechanical stress as structural materials and can be used in a wide temperature range and harsh chemical and physical environments.

Engineering plastics can be divided into two categories: general engineering plastics and special engineering plastics. General engineering plastics usually refer to five types of plastics that have been produced on a large scale and have a wide range of applications, namely polyamide (nylon, PA), polycarbonate (polycarbonate, PC), polyoxymethylene (POM), polyester (mainly PBT), and polyphenylene oxide (PPO).

And special engineering plastics refer to plastics with superior and unique properties, such as "plastics", "engineering plastics", "modified plastics" and other industry knowledge, massive material super physical property tables, numerous material selection cases, cost reduction and efficiency improvement solutions. Welcome to "Plastic Library Network" to solve these problems! However, most of the plastics that have not yet been industrialized on a large scale or have relatively small production scales and narrow applications, such as polyphenylene sulfide (PPS), polyimide (PI), polysulfone (PSF), polyetherketone (PEK), liquid crystal polymer (LCP), etc.

2、 Domestic production development status

Engineering plastics have excellent performance and can replace metals as structural materials. Therefore, they are widely used in fields such as electronics, transportation, mechanical equipment, and daily necessities, and their position in the national economy is becoming increasingly prominent.

The technological development of engineering plastics in China has a history of nearly 40 years. Although it has a certain technological foundation, there is a huge gap between China and foreign countries in terms of technical level, production capacity, and output. Some varieties (such as PPO) are still basically vacant.

In terms of business scale, most engineering plastic enterprises in China have production facilities or industrial testing facilities at the thousand ton level, while foreign enterprises have an annual production capacity of over ten thousand tons. 【 Learn more about industry knowledge such as' plastics', 'engineering plastics',' modified plastics', etc., massive material super property tables, numerous material selection cases, cost reduction and efficiency improvement plans, welcome to enter the 'Plastic Warehouse Network' to solve! 】. The huge differences in scale and technological level make it difficult for domestic engineering plastics to meet the demand of the domestic market, and their product performance and price cannot compete with imported products.

3、 Characteristics and Applications of the Five General Engineering Plastics

Polyamide (PA) has gained attention due to its unique low specific gravity, high tensile strength, wear resistance, good self-lubricating properties, excellent impact toughness, and both rigidity and flexibility. In addition, it is easy to process, efficient, lightweight (only 1/7 of metals), and can be processed into various products to replace metals. It is widely used in the automotive and transportation industries. Typical products include pump impellers, fan blades, valve seats, bushings, bearings, various instrument panels, automotive electrical instruments, cold and hot air regulating valves, and other components. Approximately 3.6 to 4 kilograms of nylon products are consumed per car. Polyamide has the largest consumption proportion in the automotive industry, followed by electronic and electrical products.

Although polycarbonate (PC) is a thermoplastic resin, it has strength similar to non-ferrous metals, as well as ductility and toughness. Its impact strength is extremely high, and it cannot be destroyed by hammering with a hammer. It can withstand the explosion of television fluorescent screens.

Polycarbonate has excellent transparency and can be applied with any coloring. Due to the excellent properties mentioned above, polycarbonate has been widely used in various safety lampshades, signal lights, transparent protective panels for sports venues and sports fields, daylighting glass, high-rise building glass, car reflectors, windshield panels, airplane cockpit glass, and motorcycle driving helmets. The largest markets for usage are computers, office equipment, automobiles, replacement glass, and sheet materials.

Polyoxymethylene (POM) is known as "super steel" due to its superior mechanical and chemical properties. Therefore, it can be used as a material that many metal and non-metal materials cannot handle. It is mainly used for various high-precision small module gears, geometrically complex instrument precision parts, water faucets, and explosion pipeline valves. The use of formaldehyde in agricultural sprinkler irrigation machinery in our country can save a lot of copper materials.

Polybutylene terephthalate (PBT) is a thermoplastic polyester. Compared with other thermoplastic engineering plastics, non reinforced PBT has better processing and electrical properties. 【 Learn more about 'plastics',' engineering plastics', 'modified plastics' and other industry knowledge, massive material super physical property tables, numerous material selection cases, cost reduction and efficiency improvement solutions. Welcome to the' Plastic Library Network 'to solve it! 】. PBT has a low glass transition temperature and can rapidly crystallize at a mold temperature of 50 ℃, with a short processing cycle.

Polybutylene terephthalate (PBT) is widely used in the electronics, electrical, and automotive industries. Due to its high insulation and temperature resistance, PBT can be used as a flyback transformer for televisions, automotive distribution panels and ignition coils, office equipment casings and bases, various automotive exterior components, air conditioning fans, electronic stove bases, and office equipment casings.

Polyphenylene oxide (PPO) resin has excellent physical and mechanical properties, heat resistance, and electrical integrity, as well as low moisture absorption, high strength, and good dimensional stability. Its creep resistance at high temperatures is the best among all thermoplastic engineering plastics. Can be applied to small household appliances such as washing machine compressor covers, vacuum cleaner housings, coffee utensils, hair styling devices, massage machines, microwave ovens, etc. Modified polyphenylene ether is also used in connectors for television components and telecommunication terminal equipment.