Engineering plastics, as a type of high-performance polymer material, have excellent mechanical properties and dimensional stability. They can withstand mechanical stress, maintain stability over a wide temperature range, and even continue to perform well in harsh chemical and physical environments. Common engineering plastics include ABS, nylon, and polysulfone, which play a crucial role in numerous engineering fields.

Engineering plastics, as a type of high-performance polymer material, play a crucial role in the field of engineering. They not only possess excellent mechanical performance and dimensional stability, but also continuously demonstrate excellent performance in various environments. According to different classification standards, engineering plastics can be divided into two categories: one is general engineering plastics, mainly including polyamide (nylon, PA), polycarbonate (PC), polyoxymethylene (POM), polybutylene terephthalate (PBT), and polyphenylene oxide (PPO), which have been produced on a large scale and have a wide range of applications; Another type is special engineering plastics, such as polyphenylene sulfide (PPS), polyimide (PI), polysulfone (PSF), polyether ether ketone (PEEK), and liquid crystal polymer (LCP), which have more excellent and unique properties. However, most of them have not yet been industrialized on a large scale or have relatively small production scales and narrow applications.

1. Polyamide (PA, commonly known as nylon)

Polyamide, also known as nylon, is a type of polymer composed of repeating amide units. The synthetic raw materials are mainly divided into two categories: one is obtained through the condensation reaction of dicarboxylic acids and diamines, and the other is prepared through the condensation reaction of alpha amino acids or the ring opening polymerization reaction of caprolactam.

2 Polyamide (PA, commonly known as Nylon)

It has received widespread attention due to its unique properties. It has a lightweight specific gravity, only about 1/7 of metal, while also possessing high tensile strength, excellent wear resistance, and self-lubricating properties. In addition, polyamide exhibits excellent impact toughness and a balance of rigidity and flexibility, making the processing process simple and efficient.

The modification research on polyamide mainly focuses on multiple aspects such as reinforcement, toughening, flame retardancy, filling, and alloying. Among them, blending extrusion technology is widely used, which can prepare polyamide materials with higher strength and heat deformation temperature by mixing inorganic or organic fibers, fillers and polyamide matrix. The common reinforced polyamide products in the market include reinforced PA6, reinforced PA66, reinforced PA46, reinforced PA1010, and reinforced PA610, among which the production of reinforced PA6 and PA66 is particularly prominent. In terms of reinforcing materials, glass fiber, carbon fiber, aramid fiber, and inorganic whiskers have been widely used.

The product has a wide range of applications, especially playing a key role in the automotive and transportation industries. Nylon products, such as pump impellers, fan blades, valve seats, bushings, bearings, and various instrument panels, are essential components in the automotive industry. The average consumption of nylon products per car is as high as 3.6-4 kilograms, indicating a huge proportion of polyamide consumption in the automotive industry. In addition, the electronic and electrical field is also one of the important application areas of polyamide.

3. Polycarbonate (PC)

Polycarbonate, abbreviated as PC, is a high molecular weight polymer containing carbonate groups. The structural types of its ester groups can be divided into various types such as aliphatic, aromatic, and aliphatic aromatic. This material can be synthesized through the condensation reaction of bisphenol A and diphenyl carbonate.

Polycarbonate (PC) combines metallic strength with excellent ductility and toughness, and its impact resistance is also outstanding. In addition, the resin has excellent transparency and is easy to color.

4 Polycarbonate (PC)

Its application is extensive and covers many fields. It is used as a key component of lighting equipment such as safety lampshades and signal lights, and also plays an important role in transparent protective panels for sports venues and sports fields, as well as in daylighting glass and high-rise building glass. In addition, the automotive manufacturing industry is also an important application area for polycarbonate, including components such as mirrors and windshield panels that cannot be separated from its presence. In the aerospace field, this high-performance resin is also used for aircraft cockpit glass and motorcycle driving helmets. In terms of market demand, polycarbonate has the highest demand in markets such as computers, office equipment, automobiles, substitute glass and sheet materials, as well as CD and DVD discs, especially the latter. With the continuous popularization of digital media, its market potential is increasingly evident.

5. Polyoxymethylene (POM)

Polyformaldehyde, also known as polyformaldehyde, is a linear polymer with no side chains, high density, and good crystallinity. This polymer can be further divided into two categories based on the different chemical structures in its molecular chain: homopolymer formaldehyde and copolymer formaldehyde.

Homoformaldehyde, a major invention of DuPont in 1959, has a complex production process. Firstly, refined formaldehyde is obtained through the reaction of formaldehyde solution with isooctanol, followed by dehydration, thermal cracking, and other steps. Subsequently, under the action of a catalyst, refined formaldehyde undergoes liquid-phase polymerization and is capped by acetic anhydride esterification. In the end, we obtained homoformaldehyde with high crystallinity and narrow molecular weight distribution, with a relative density of about 1.4 and a melting point range between 170-185 ℃.

On the other hand, the technology of co formaldehyde is represented by Hirst Seranis company. They concentrated a 50% formaldehyde solution to 65% and synthesized a trimeric formaldehyde solution under the catalysis of sulfuric acid. After solvent extraction and refining, trimeric formaldehyde suitable for polymerization is obtained. Next, using this polymer grade formaldehyde as the main monomer, copolymerization is carried out with ethylene oxide (or dioxolane), and bulk continuous copolymerization is carried out through a twin-screw reactor. This process can be divided into two stages: high-temperature pressure polymerization and segmented deep polymerization. The final copolymer is subjected to pulverization, continuous stabilization, and intermittent stabilization treatment to remove thermally unstable components. After drying, additives are mixed for granulation to produce granular copolymer formaldehyde products.

6 Polycarbonate (PC)

It has a metallic hardness and strength, while also possessing rigidity, making it exhibit excellent self-lubricating and fatigue resistance in a wide range of temperature and humidity environments, as well as being elastic. In addition, polycarbonate also has excellent chemical resistance, hence it is known as "steal steel" and "super steel". Among various application fields, polycarbonate can replace metals such as zinc, brass, aluminum, and steel to make various components. Its applications have spread to many fields such as electronics and electrical, machinery, instrumentation, daily light industry, automobiles, building materials, and agriculture. In recent years, with the development of emerging fields such as medical technology and sports equipment, the application of polycarbonate has also shown strong growth momentum.

7 Polybutylene terephthalate (PBT)

Polybutylene terephthalate (PBT) is a thermoplastic polyester resin made by the condensation reaction of 1,4-butanediol with terephthalic acid (PTA) or terephthalate (DMT), followed by a mixing process. It presents a semi transparent or slightly opaque state, with crystallinity, a milky white or light yellow appearance, a smooth surface, a density range of 1.31 to 1.55 grams per cubic centimeter, and a relative molecular weight of about 30000 to 40000.

8 Polybutylene terephthalate (PBT)

It has many significant characteristics. Firstly, its mechanical performance is outstanding, manifested by high strength, excellent fatigue resistance, and stable size, with almost no creep even in high temperature environments. Secondly, after enhancing the heat aging resistance of PBT, its UL temperature index can reach 120-140 ℃, making it very suitable for long-term outdoor use. In addition, it also has good solvent resistance and no stress cracking phenomenon. In terms of stability, PBT is not easily decomposed when exposed to water, ensuring its durability in use. At the same time, its insulation performance is also quite excellent, and it can maintain stable electrical performance in both humid and high-temperature environments, making it an ideal choice for manufacturing electronic and electrical components. In addition, the dielectric constant of PBT is 3.0-3.2, and its arc resistance reaches 120 seconds, further enhancing its electrical performance. In terms of molding processing, PBT has good fluidity, fast crystallization speed, and low requirements for mold temperature. Whether processing thin-walled parts or large components, it can be completed in a short period of time with extremely high efficiency.

9 Polybutylene terephthalate (PBT)

It has a wide range of applications in multiple fields. The electronics and electrical industry is one of its main application areas, and its high insulation and temperature resistance make it an ideal choice for TV flyback transformers, automotive distribution boards, and ignition coils. In addition, PBT is often used to manufacture the shells and bases of office equipment, exterior components of automobiles, air conditioning fans, and electronic stove bases. Its excellent mechanical performance and stability make these products durable in various environments.

10 Polyphenylene Ether (PPO)

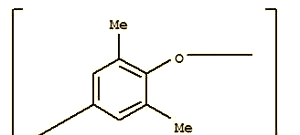

Polyphenylene ether, also known as poly (2,6-dimethyl-1,4-phenyl ether), is commonly abbreviated as PPO or PPE. This thermoplastic resin is prepared by oxidative coupling polymerization of 2,6-disubstituted phenol. In the production process, commonly used polymerization methods include precipitation polymerization and solution polymerization.

11 Polyphenylene Ether (PPO)

characteristic:

Physical and mechanical properties: The molecular chain of polyphenylene ether is rich in benzene rings, giving it excellent rigidity and mechanical strength, as well as high hardness and toughness. Its creep tendency is small and its dimensional stability is excellent.

Thermal performance: Polyphenylene ether exhibits excellent heat resistance, with a glass transition temperature of up to 211 ℃, a melting point of 268 ℃, and a thermal decomposition temperature of 330 ℃.

Electrical performance: The lack of strong polar groups in the molecular structure of polyphenylene ether enables it to maintain good electrical performance over a wide range of temperatures and frequencies. Its dielectric constant and dielectric loss tangent are at a relatively low level in engineering plastics and are not affected by temperature, humidity, and frequency changes.

Chemical properties: As an amorphous resin, the molecular structure of polyphenylene ether does not contain hydrolyzable groups, thus it has excellent water resistance. Its products are durable and stable in high-pressure steam. However, it is soluble in organic solvents such as halogenated fatty hydrocarbons and aromatic hydrocarbons.

Disadvantages:

Strong fluidity: Polyphenylene ether is highly mobile, making it difficult for pure resin to be injection molded.

Surface roughness: After adding glass fiber reinforcement or filling, the surface of the product often becomes rough and the glossiness decreases.

High cost: Compared to general engineering plastics, the cost of polyphenylene ether is about twice as high.

Insufficient impact strength: The impact strength of polyphenylene oxide products is relatively poor, manifested as brittleness, and the welding strength is also not ideal.

Poor coating and coloring properties: Due to the excellent chemical resistance of polyphenylene ether, its coating and coloring properties are relatively unsatisfactory.

12 Polyphenylene Ether (PPO)

It has a wide range of applications and can be used to replace stainless steel in the manufacture of surgical medical instruments such as surgical handles and pliers. In the field of electromechanical industry, polyphenylene ether also performs well and can be used to make gears, blower blades, pipes, valves, screws, and other fasteners and connectors. In addition, the electronics and electrical industry is also an important application area for polyphenylene oxide, for example, it can be used as a key component for coil skeletons and printed circuit boards.

13 Polyphenylene sulfide (PPS)

Polyphenylene sulfide (PPS), also known as polyphenylene sulfide, is a thermoplastic resin containing a phenylsulfide group with a unique molecular backbone structure. This resin is mainly composed of dichlorobenzene and alkali metal sulfides, and is synthesized through solution condensation reaction in polar solvents such as N-methylpyrrolidone or hexamethylphosphoramide.

Polyphenylene sulfide (PPS) has excellent heat resistance and can work stably in a wide temperature range of 180-220 ℃. Its corrosion resistance is also impressive, comparable to polytetrafluoroethylene. In addition, PPS exhibits excellent electrical and mechanical properties, as well as good flame retardancy. However, this high-performance plastic also has its shortcomings, such as relatively high price, poor toughness, and instability of medium viscosity. Pure PPS is usually not used alone, but instead modified varieties are used, such as by adding reinforcing materials such as glass fiber and carbon fiber to enhance performance. Common enhanced PPS products in the market include 40% glass fiber reinforced PPS (R-4), inorganic filled PPS (R-8), and carbon fiber reinforced PPS (G-6). In addition, PPS is also alloyed with other plastics such as PTFE, PA, PPO, etc. to further improve its brittleness, lubricity, and corrosion resistance. For example, PPS/PTFE alloy effectively enhances these properties of PPS.

Polyphenylene sulfide (PPS) has a wide range of applications. Among them, glass fiber reinforced PPS stands out for its excellent thermal stability, wear resistance, and creep resistance. It exhibits excellent mechanical and electrical properties over a wide range of temperature, humidity, and frequency, with a small dielectric constant and low dielectric loss. This material is particularly suitable for use as a high-temperature resistant and anti-corrosion coating, and its coating can maintain stability for a long time at 180 ℃. In addition, PPS is often used as a key component in the electronic and electrical industry, such as connectors, insulation partitions, terminals, and switches. PPS is also favored in the fields of machinery and precision machinery because it is suitable for making pumps, gears, piston ring storage tanks, blade valves, clock components, and camera components. In the automotive industry, PPS also plays an important role in the manufacturing of components such as vaporizers, distributor parts, and electronic and electrical components. In the field of home appliances, PPS is also widely used in the manufacturing of structural components, crystal diodes, and various parts of magnetic tape recorders. In addition, PPS/PTFE alloy has a wide range of applications in the aerospace and aviation industries, such as making anti stick, wear-resistant components and transmission parts, such as shaft pumps.

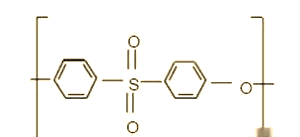

14 polysulfone (PSF)

Characteristic analysis: Polysulfone, a slightly amber colored amorphous transparent or semi transparent polymer, not only has excellent mechanical properties, but also has outstanding rigidity, wear resistance, and high strength. Its wide application temperature range is from -100 ℃ to 150 ℃, and it can be used for a long time at 160 ℃, with short-term use temperatures as high as 190 ℃. It is worth mentioning that even in such high temperature environments, polysulfone can still maintain its excellent mechanical properties, which is undoubtedly its most remarkable advantage.

Polysulfone (PSF) has a wide range of applications in multiple fields. In the field of electronics and electrical engineering, it can be used to make various contactors, connectors, transformer insulation components, as well as thyristor caps and insulation sleeves. Meanwhile, polysulfone is also suitable for automotive manufacturing, such as cover components, electric gears, and battery covers. In the aviation field, it is often used in the manufacturing of aircraft internal and external parts, spacecraft external protective covers, and camera mounts. In addition, polysulfone can also be used for lighting components, sensors, etc. in daily life.

Moreover, polysulfone also plays an important role in the food and beverage industry. It can replace glass and stainless steel to make containers such as steam plates, coffee containers, and microwave cookers. Meanwhile, the high-strength adhesion of polysulfone also makes it an ideal choice for dental implants and chemical equipment manufacturing. Polysulfone also has a wide range of applications in food processing and dairy product processing, such as the production of pipelines, valves, containers, and other equipment. In addition, it is often used in environmental protection and infection control equipment to ensure the environment and human health.

15 Polyimide (PI)

Polyimide, abbreviated as PI, is an aromatic heterocyclic polymer compound containing acyl imine chains in its molecular structure. It is mainly divided into four categories: homopolymer PI, soluble PI, polyamide imide (PAI), and polyetherimide (PEI).

Polyimide (PI) not only has excellent mechanical properties, fatigue resistance, flame retardancy, dimensional stability, and electrical properties, but also exhibits low molding shrinkage. In addition, it exhibits good resistance to oil, general acids, and organic solvents, although not alkali resistant. It is worth mentioning that PI also has excellent friction and wear resistance. More importantly, this material is non-toxic, making it very suitable for manufacturing tableware and medical equipment, and can withstand thousands of disinfection treatments. At the same time, PI has excellent heat resistance, able to withstand high temperatures up to 290 ℃ and short-term high temperatures of 490 ℃, even in liquid helium at -269 ℃ without brittle fracture. In terms of processing, PI can be molded in various ways, including compression molding, impregnation, injection molding, extrusion, die casting, coating, casting, lamination, foaming, and transfer molding.

Polyimide (PI) has a wide range of applications in multiple fields. PI plays an indispensable role in various fields such as aviation, automotive, electronics, and industrial machinery. It can be made into key components such as engine fuel supply system parts, jet engine components, compressors, and generator parts. Meanwhile, PI can also be used to produce automotive engine components such as bearings, piston sleeves, and timing gears, as well as printed circuit boards, insulation materials, heat-resistant cables, etc. in the electronics industry. In addition, the mechanical industry has fully utilized the excellent performance of PI to manufacture high-strength components such as high-temperature self-lubricating bearings, compressor blades, and piston engines.

16 Polyether Ether Ketone (PEEK)

Polyether ether ketone, abbreviated as PEEK, is a high-performance thermoplastic special engineering plastic. Its unique main chain structure contains repeated units of ketone and ether bonds, endowing it with excellent high temperature resistance, allowing it to be used for a long time at temperatures up to 250 ℃. For this reason, PEEK was once known as the "super heat-resistant special engineering plastic".

Polyether ether ketone (PEEK) not only has excellent high temperature resistance, but also exhibits many other outstanding characteristics. Its melting point is as high as 334 ℃. After being reinforced with glass fiber or carbon fiber, its short-term heat resistance can be increased to over 300 ℃, while its long-term heat resistance can reach 250 ℃ through UL temperature index (RTI). In addition, PEEK has excellent toughness and is known as a very flexible resin. Its flame retardancy is also quite excellent, reaching UL94V-0 level (1.5mm), with self extinguishing properties, and the lowest smoke emission during combustion among all resins. At the same time, PEEK also exhibits excellent corrosion resistance and chemical resistance, which can resist various solvents other than concentrated sulfuric acid. In terms of hot water resistance, it also performs well and can be stably used in steam at 200-300 ℃. In addition, PEEK has the highest fatigue and creep resistance among thermoplastic materials. In terms of processability, PEEK is not only injection molded, but also suitable for various other molding methods.

Significant progress has also been made in the modification research of polyetheretherketone (PEEK). J. Denault and Lin SH et al. effectively improved the temperature, rigidity, dimensional stability, and impact performance of PEEK by introducing composite materials such as glass fiber (GF) and carbon fiber (CF). The filling of nanomaterials further enhances the hardness, tensile strength, and tensile modulus of PEEK composite materials, with an increase of 20% -50%, providing possibilities for their application in more fields.

Polyether ether ketone (PEEK) has a wide range of applications in various fields. It is often used as an insulation or protective layer for cables and wires, and its excellent high temperature resistance enables it to play an outstanding role in high-end fields such as atomic energy, aircraft, and ships. In addition, PEEK can also be used to manufacture connectors and valve parts for atomic power plants, as well as battery slots and engine components for rockets. Even through blow molding technology, PEEK can be made into nuclear waste containers, demonstrating its excellent corrosion and radiation resistance.

10 Liquid Crystal Polymer (LCP)

Liquid crystal polymer (LCP) is a high-performance engineering plastic that emerged in the early 1980s, covering multiple types such as lyotropic liquid crystal polymer (LLCP), thermally responsive liquid crystal polymer (TLCP), and pressure responsive liquid crystal polymer. This polymer resin usually appears as a beige color, sometimes also as a white opaque solid powder, with a density range of 1.4 to 1.7 grams per cubic centimeter.

LCP is renowned for its excellent mechanical properties, heat resistance, flame retardancy, dimensional stability, radiation resistance, electrical performance, and chemical corrosion resistance, while also possessing outstanding molding and processing characteristics.

Liquid crystal polymer (LCP) has a wide range of applications in various fields. Firstly, due to its high strength, rigidity, high temperature resistance, and superior electrical insulation, LCP plastic raw materials are widely used in industries such as electronics, electrical, optical fiber, automotive, and aerospace. In addition, liquid crystal fibers can be used to make fishing nets, sports equipment, brake pads, as well as optical fibers and display materials, and can even be made into thin films, suitable for fields such as flexible printing circuits and food packaging.

The high and low temperature resistance of LCP plastic raw materials makes it an ideal choice for microwave oven containers. At the same time, it is also used to produce high-end products such as printed circuit boards, electronic components for artificial satellites, and jet engine parts. LCP also has a wide range of applications in the fields of electronics and automotive machinery, even extending to the medical industry.

In addition, LCP plastic raw materials can be mixed with polysulfone PBT、 Polyamide and other plastics are blended to produce alloy materials with higher mechanical strength. This alloy material can not only replace plastics such as glass fiber reinforced polysulfone, but also improve mechanical strength, service strength, and chemical stability. At present, research on the application of LCP in high-end fields such as spacecraft exterior panels and automotive exterior braking systems is also underway.