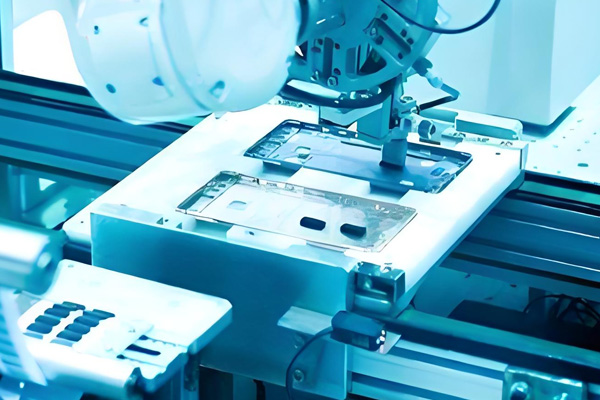

Engineering plastics are widely used in the electronic high-tech industry, and their excellent performance meets the needs of electronic products for lightweight, high temperature resistance, insulation, and design flexibility. The following are its specific applications and examples:

1. Structural components and shell

Materials: polycarbonate (PC), ABS alloy, polyamide (nylon)

Application: Mobile phone, laptop shell, internal bracket.

Advantages: PC is impact resistant, transparent and aesthetically pleasing; ABS alloy bonding strength and surface smoothness; Nylon is wear-resistant and suitable for sliding parts.

2. Insulation and high temperature resistant components

Materials: Polyphenylene sulfide (PPS), liquid crystal polymer (LCP), polybutylene terephthalate (PBT)

Applications: Circuit board substrates, connectors, relays.

Advantages: PPS can withstand high temperatures of 260 ℃; LCP high fluidity is suitable for micro connectors; PBT arc resistant, used for power modules.

3. Thermal conductivity and heat dissipation management

Material: Modified polyamide (with added boron nitride and graphite)

Application: Heat sink, LED lampshade, 5G base station casing.

Advantages: By using thermal conductive fillers to improve heat dissipation efficiency and replace metals to reduce weight.

4. Precision connectors and miniaturized components

Materials: LCP, polyetheretherketone (PEEK)

Application: High frequency connectors, miniature sensors.

Advantages: LCP has low dielectric loss and is suitable for 5G high frequency; PEEK is fatigue resistant and used for precision gears.

5. Environmental protection and flame retardant requirements

Materials: halogen-free flame retardant PC/ABS, polyoxymethylene (POM)

Application: Charger casing, internal cables.

Advantages: Compliant with RoHS standards, with a flame retardant rating of UL94 V-0.

6. Emerging application areas

5G communication: LCP antenna substrate with low dielectric constant to reduce signal loss.

Wearable devices: Thermoplastic polyurethane (TPU) flexible and durable, used for watch straps.

Flexible electronics: Polyimide (PI) film is used as a flexible screen substrate, which is resistant to high temperature bending.

Summary of Core Advantages

Lightweight: Replace metal and reduce equipment weight.

Insulation: Ensure circuit safety and prevent short circuits.

High temperature resistance: Suitable for the heat dissipation needs of high-power components.

Design freedom: Complex structure injection molding, supporting miniaturization.

Environmental compliance: Halogen free flame retardant meets global regulations.

Future Trends

High frequency material development: to cope with 5G/6G high-frequency signal transmission.

Biobased plastics, such as polylactic acid (PLA), reduce carbon footprint.

Intelligent material integration: self-healing plastics extend equipment lifespan.

Engineering plastics continue to drive innovation in the electronics industry, and will deepen their application in high-performance and sustainable directions in the future, supporting the development of intelligence and green technology.